Tel: +86-13777263762

Email: [email protected]

Tel: +86-13777263762

Email: [email protected]

Did you know that car is a product? It’s really interesting! Metal StampingAccording to GM, cars are made through a process called Metal stamping. This consists of producing big metal sheets from scratch, which is one then ultrasonically slices and carves a sheet into individual parts of the vehicle: as an example doors or engine[5] It should also be stressed that the production of metallic parts is not so easy. This is precision engineering at heart. Which is to say, all has be measured & cut correctly otherwise they do not fit together like a Puzzle.

Companies use high quality materials and unique techniques to produce the parts in order to create more advanced car gear. I mean there are specific circumstances when some types of steel really strong and is extremely important for safety, say a windshield. The coats represent only a stripe width (B60) in themselves, but they help prevent the metal surface from rust and corrosion. Benefits of car part longevity Deep Drawing is a method they use sometimes, instead of just stamping metal sheets. Called sheet forming, this method uses place to pull a thin metal up into the complex shape almost like clay can be shaped on laying. The biggest advantage of this is to create a very designed parts that match the car.

Creating these boutique car parts can be very expensive and take a lot of time. This is why companies are continuously seeking ways to save on costs and make work more efficient. A neat way they do this is by computer simulations. Thanks to these simulations, they are able to explore different designs before finalizing the parts. This allows them to determine the best and most economical way for cutting metal sheets that can result in a significant amount of savings over time. Advanced equipment is also used that can quickly and accurately stamp out the parts needed to ensure production remains on time.

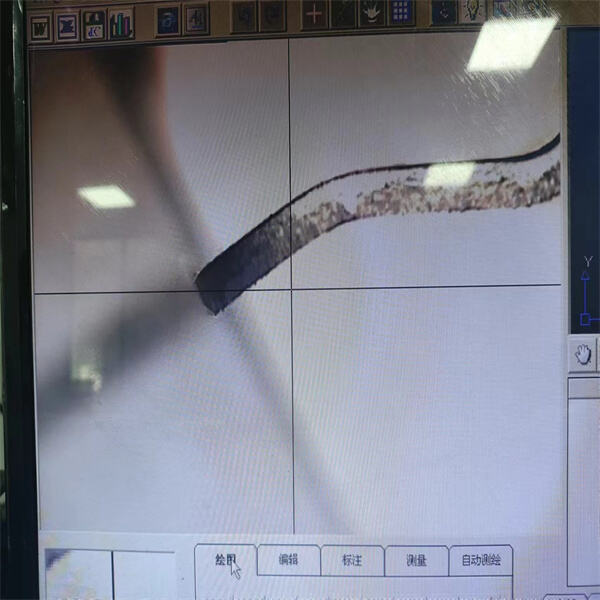

Although these methods are smart, it is still a hard task to create reliable metal parts of good quality for cars. There is a talent and hustle-wage. Fortunately, new technology is allowing companies to produce stronger, lighter and all-around better parts than ever before. For example, some manufacturers now cut the metal sheets using lasers. In such a way this technology allows them to design extremely sharp edges of parts, that is essential for their conjugation. 3D printing is also being used by other companies to produce molds and prototypes. This also allows them to try out new designs and materials before they are put into production fully.

Custom car part production for different brands is one of the things that matters most in metal stamping. This means that they have to manufacture parts intended for use only with specific car models i., Honda Civic or Toyota Camry. Cars of each type have different requirements and making parts that perfectly align with those needs is critical to the safety & performance of your vehicle. In some cases, companies have gone so far as to partner with car manufacturers in designing and testing new parts. These partnerships assure that the components will perform flawlessly and remove any doubt from safety issues.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. All Rights Reserved - Privacy Policy