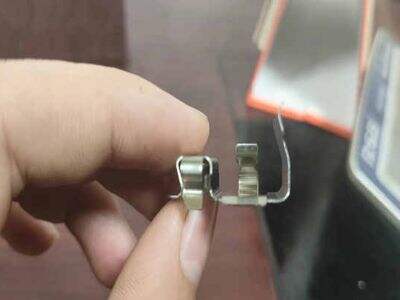

Metal stamping is a process we rely on when we make metal objects, such as cars or tools for the kitchen. So, metal stamping uses precise tools known as precision tooling to press metal into various types of shapes. They are critical tools enabling the metal pieces to be precisely the right dimensions.

What is Metal Stamping and How Precision Tooling Assists It

Metal stamping is more efficient, faster and more intricate when precision tooling is employed. We can do the things in the best way possible. The use of precision tooling adds more simplicity and reduces time consumption. And so without further ado, let us discuss how precision tooling aids metal stamping.

Precision Tools Making Production Easier

Precision tooling is essential for easing production in the fields of metal stamping. Making them easier allows us to do them faster. Precision tooling ensures all the metal work pieces are being made the same way and to the same quality. It saves time and eliminates mistakes, so the production process runs smoothly.

VauntThe 10-Minute Guide to Metal Stamping Tools to Get More Done

metal stamping kit are very important to achieve more in metal stamping. Being more productive means creating more products. This is better than the traditional methods as precision tooling is used to produce metal stamping tools which are high quality and can produce more metal pieces in less time. This allows for more products to be created that helps the company grow and provide for more customers.

To Innovate Metal Stamping with Technology

Precision leather stamping tools is more effective with the help of technology. Improving is to make something better. Noise Control Technology | Precision tooling technology is used to create tools that work with greater speed and accuracy. It can help streamline metal stamping, saving the company time and resources.

Effects Of Precision Tooling On Metal Stamping Process

Metal stamping productivity is directly impacted by precision tooling. Performance is how well something works. Precision tooling ensures that every single metal piece is made to the same precision and accuracy. This improves metal stamping process and thus higher quality products.

Better Precision Tooling for Higher Quality, Faster

For a metal stamping process, improved quality and speed are achievable through better precision tooling. Quality - how good something is. This QMP program is a requirement for suppliers of components or materials which require precision tooling. This accelerates the metal stamping process, which helps manufacturers produce parts more quickly, and better.

To summarize, leather for stamping is of utmost significance for achieving improved metal stamping outcome. Precision tooling helps companies like WenZhou to manufacture metal products quickly and effectively by streamlining production, getting more done with the right tools, improving efficiency through technology, influencing performance, and improving quality and speed through better tooling. Precision tooling is everything when it comes to metal stamping, and knowing this is the key to creating quality products and satisfied customers.

EN

EN