Tel:+86-13777263762

E-mail:[email protected]

Tel:+86-13777263762

E-mail:[email protected]

Você já viu como um carro é fabricado? É um processo tão fascinante que você precisa ser dedicado, criativo e vigilante. No final, um carro não é apenas uma junção de peças, mas passa por muitos passos e cada um desses passos tem grande importância para nos fornecer veículos seguros e padronizados. Além disso, um passo essencial na fabricação de automóveis é o estampagem do metal em chapas. Este é o processo no qual chapas metálicas são moldadas para formar diferentes partes do carro, como portas, capô e para-lamas. Esse processo é realizado usando ferramentas especiais conhecidas como matrizes de estampagem automotiva. Neste artigo, vamos explorar mais profundamente o que são essas ferramentas e o valor que elas proporcionam.

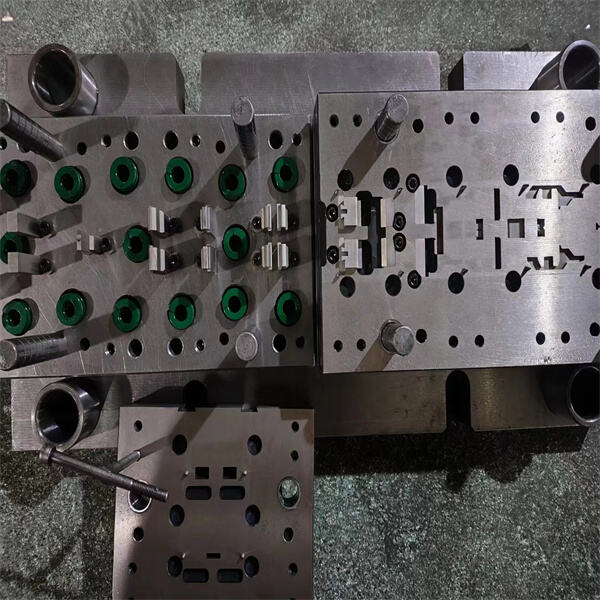

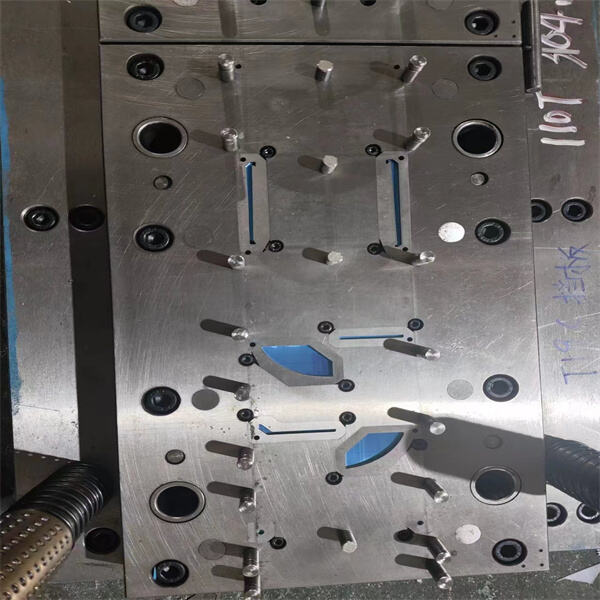

Ferramentas de estampagem automotiva são ferramentas especiais que ajudam a criar uma forma específica a partir da chapa metálica. Cada uma dessas ferramentas foi feita sob medida para atender às necessidades peculiares de cada empresa de customização. Isso é para garantir que cada peça esteja em perfeita alinhamento com as outras peças do seu veículo. Uma matriz de estampagem é utilizada para empurrar o metal diretamente para a forma, de modo que um componente adequado possa ser criado. Ser preciso nesta etapa é crucial, assim como era importante obter a leitura correta da sua mão. Se uma peça não estiver funcionando normalmente, isso afeta a economia de escala quando montado.

Enquanto os carros se tornam mais avançados, as ferramentas para criá-los também precisam evoluir. Sempre surgem novas técnicas de design para ajudar a melhorar o desempenho e a eficiência dos moldes de estampagem. Isso inclui o time de engenharia, para o qual ferramentas como simulações computacionais e impressão 3D permitem que engenheiros desenvolvam modelos físicos sobre moldes de estampagem. Isso mostra como o molde irá se comportar antes mesmo de ser fabricado. Essas tecnologias permitem que os engenheiros criem formas mais precisas e sejam mais ousados na seleção do design. Fabricantes sempre tentaram, de alguma forma (e claro, sem sucesso), um melhor design para fixadores automotivos usando seu processo de fabricação de carros.

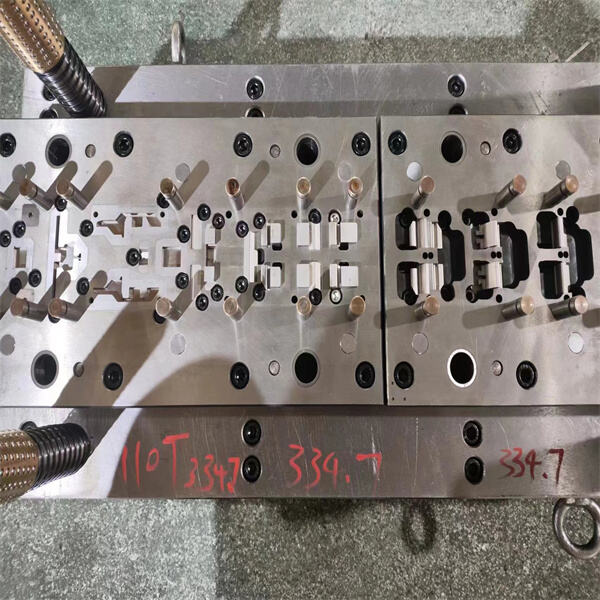

Os moldes de estampagem utilizam materiais importantes. Eles são escolhidos por sua força e robustez; exemplos incluem arame de aço, carbeto. Alguns desses metais podem resistir a uma quantidade elevada de pressão e fornecer integridade estrutural através de muitas estampagens. Materiais de qualidade, quando usados corretamente, garantem que sejam duráveis e continuem performando bem durante toda a vida útil para moldes de estampagem simples. Isso pode economizar tempo e dinheiro a longo prazo, pois essas peças não precisarão ser substituídas ou reparadas com tanta frequência. Materiais fortes ajudam a garantir que os moldes de estampagem continuem funcionando corretamente, assegurando veículos seguros e confiáveis.

Criar carros é tudo sobre ser eficiente. Os Fôrmas de Estampagem Automotiva ajudam na automação dos processos de fabricação e economizam no desperdício. O carro é rápido e preciso no suporte, então tudo funciona de forma eficiente. Isso é muito útil em uma fábrica onde muitos carros estão sendo produzidos simultaneamente. Além disso, a produção de uma variedade de peças é longa e elimina a maioria das fôrmas de estampagem. Com a ajuda dessas ferramentas, os fabricantes podem produzir carros mais rapidamente e manter padrões de alta qualidade.

O setor automotivo é uma indústria em constante mudança e continuamente traz novas tendências. Considere o alumínio como um exemplo que atualmente está sendo investigado por várias empresas. Isso poderia potencialmente ajudar a reduzir o consumo de combustível dos carros, levando a um ambiente mais limpo. Isso está causando o desenvolvimento de matrizes de estampagem para esses novos materiais, disse Learn para garantir que eles sejam formados corretamente. Mais carros estão se tornando elétricos++ +_REFERER_ACTUAL++; Como esses veículos têm necessidades técnicas diferentes dos carros tradicionais, as matrizes de estampagem automotiva também precisam se adaptar às mudanças. As Matrizes de Estampagem Devem Acompanhar os Avanços na Tecnologia

Copyright © Ningbo Wenzhou Technology Co.,Ltd. Todos os Direitos Reservados - Política de Privacidade