Tel:+86-13777263762

E-mail:[email protected]

Tel:+86-13777263762

E-mail:[email protected]

Os moldes de dobra são conhecidos como ferramentas especializadas que dão forma e tamanho ao metal. Não podemos enfatizar o suficiente quão benéficos eles são para muitas indústrias, além de incontáveis outras funções. Eles podem fabricar peças para carros, pontes resistentes e esculturas impressionantes. Neste post, explicaremos como usar moldes de dobra e qual é o mais adequado para sua aplicação, mencionando algumas maneiras de mantê-los em boas condições.

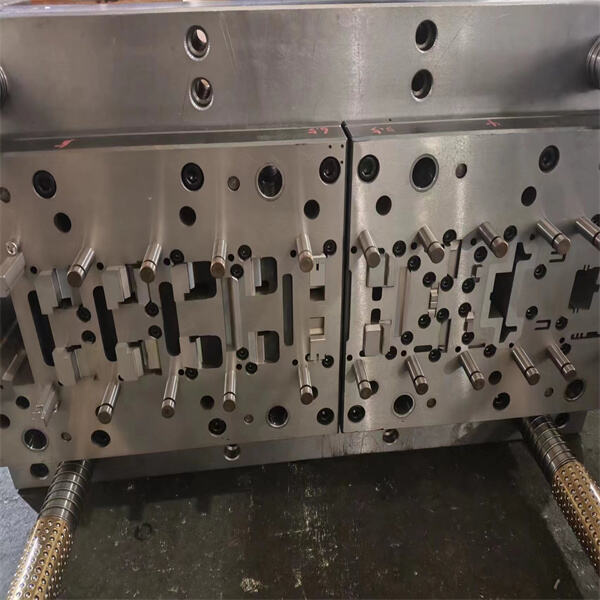

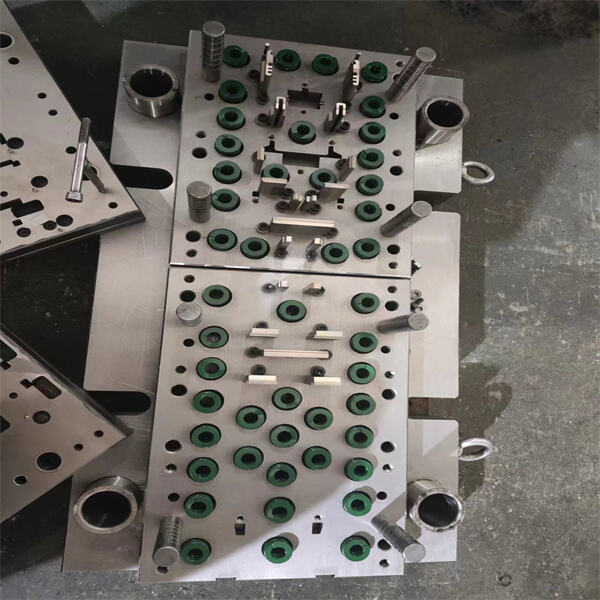

Ao pressionar a superfície metálica, os moldes de dobra fazem com que ela se curve e assuma uma nova forma. Eles são compostos por vários componentes que trabalham juntos para alcançar esse objetivo. O punch (punch konsi hot ima laging) pressiona o metal na direção da curvatura. O molde é a parte que segura e suporta o metal enquanto ele está sendo modelado. Em seguida, há o Pressure Pad, onde aplicamos força oposta ao metal. Quando o metal é tão macio e maleável, ele não vai se dobrar onde não queremos que dobre (eles atuarão como guias).

Quando você deseja um molde de dobra, certifique-se de que ele seja o adequado para os seus propósitos pretendidos. Todos os metais e formas de metal requerem diferentes moldes. Tamanho Padrão -> Moldes Personalizáveis. Mais uma vez, essas opções também estão disponíveis para você durante a parte de dobra. Esses métodos são dobra a ar, dobra inferior e cunhagem. Ambos os métodos são capazes de ajudá-lo a obter o tipo exato que se adapta às suas necessidades, então é bom entender ambos.

Uma das melhores coisas ao usar matrizes de dobra é que elas fornecem formas precisas e específicas a cada vez. Isso é muito superior a tentar dobrar metal à mão, o que pode ser um pouco complicado e tende a deixar imperfeições. Dessa forma, se você estiver trabalhando em projetos massivos que precisam de furos precisos, as matrizes de dobra permitirão que todas as suas peças se encaixem facilmente sem nenhum problema. Sua alta precisão pode ser vital em indústrias onde pequenos erros podem levar a grandes problemas.

Para garantir que suas matrizes de dobra funcionem bem e durem muito tempo, é necessário cuidar delas adequadamente. Às vezes, é necessário fazer manutenção regular, limpando-as após cada uso e verificando se alguma parte está desgastada, substituindo essas partes. No entanto, também é essencial manter as matrizes de dobra seguras para que não enferrujem ou fiquem obsoletas. Claro, mantê-las bem lubrificadas é outro passo importante, pois isso reduz significativamente o atrito e previne que as ferramentas fiquem presas ou desgastem rapidamente.

Aqui estão algumas coisas importantes a ter em mente ao decidir qual ferramenta de dobra escolher: Primeiro, considere o tipo de metal com o qual você está trabalhando. Diferentes metais podem precisar de diferentes ferramentas. Nesta parte, pense também na espessura do metal; se for chapa grossa, será necessário uma ferramenta maior. Além disso, considere a forma em que deseja moldar. Imagine que você está iterando um pouco mais: ter uma ideia do tipo de design em mente pode ser ótimo. O custo da ferramenta de dobra é outro fator a considerar. Alguns desses podem ser caros, então saiba quanto você quer gastar. Por último, considere se você prefere seu sistema manual ou automatizado; ambos têm suas vantagens e desvantagens.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. Todos os Direitos Reservados - Política de privacidade