Tel:+86-13777263762

E-mail:[email protected]

Tel:+86-13777263762

E-mail:[email protected]

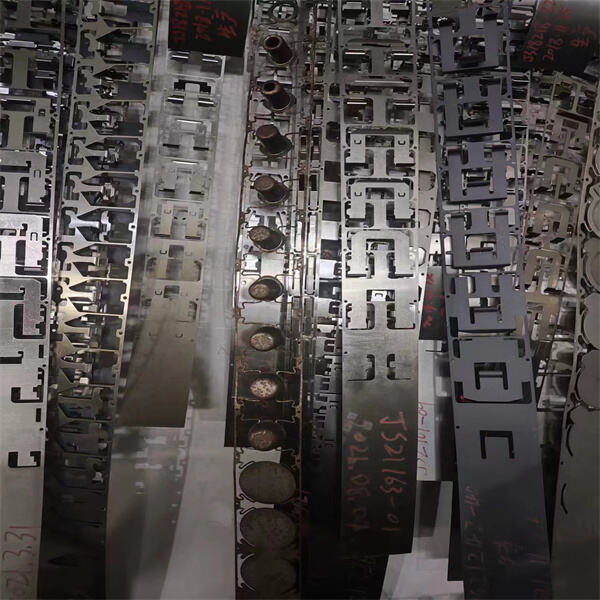

Quantas vezes você também viu algumas pequenas peças metálicas brilhantes dentro de uma máquina, brinquedo ou até mesmo na sua bicicleta? Se você já viu, é provável que tenham sido produzidas usando um processo único chamado estampagem por matrizes progressivas. Essa técnica inclui o corte, dobra e modelagem de chapas metálicas com design personalizado utilizando ferramentas avançadas. É um processo interessante e que ajuda a formar muitos dos itens que usamos no dia a dia. Mas primeiro, um pouco sobre por que esse processo é tão incrível e importante!

Velocidade de produção. Um dos benefícios mais notáveis da estampagem a quente é como ela ajuda na criação de peças mais rapidamente. Isso significava que os fabricantes podiam produzir em massa muitas peças idênticas simultaneamente. Isso é importante porque economiza tempo e dinheiro. Com menos máquinas e trabalhadores necessários, os custos se acumulam, permitindo que a produção avance em um ritmo acelerado!

Outra vantagem é que as peças produzidas por meio de estampagem por matriz progressiva geralmente têm qualidade consistente e confiável ao longo do processo. Essas máquinas cortam e modelam com muita precisão, o que é quase impossível para uma pessoa fazer. Isso permitirá que as peças se encaixem um pouco melhor entre si e realizem suas funções de maneira mais eficaz.

À medida que a chapa metálica passa por esta máquina de alta velocidade e potente, as ferramentas superiores da prensa trabalham em coordenação com o leito inferior fixo para cortar/formar/shape a peça apropriada. Você usará diferentes ferramentas durante o processo para gradualmente construir seu design final. É um processo lento, mas preciso fazê-lo no meu próprio ritmo para que cada pequeno detalhe fique perfeito.

Ferramenta de Estampagem Progressiva e Precisão Isso garante que as peças finalizadas sejam robustas e de boa qualidade na acabamento. Pequenos erros na fase de corte ou modelagem do aço podem se tornar problemas significativos durante a produção do produto final. Se as peças não se encaixarem corretamente, isso pode levar a falhas funcionais.

Essa precisão é obtida usando programas de computador especiais que projetam as tormakines de chapas metálicas e os cortes. Eles também utilizam ferramentas de medição muito precisas para garantir que cada parte seja fabricada exatamente como deve ser. Este nível de precisão é o motivo pelo qual oficinas de estampagem progressiva têm tanto sucesso.

A seleção de materiais adequados também é fundamental para garantir a resistência e um ciclo de vida mais longo das peças fabricadas. Diversas aplicações são atendidas por uma ampla gama de metais e ligas, cada uma com propriedades que permitem o seu uso em diferentes contextos. Aço: O aço é frequentemente usado por suas melhores propriedades, como resistência e durabilidade, que geralmente são necessárias em peças funcionais. Esses são os melhores para usos intensos.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. Todos os Direitos Reservados - Política de Privacidade