Tel:+86-13777263762

E-posta:[email protected]

Tel:+86-13777263762

E-posta:[email protected]

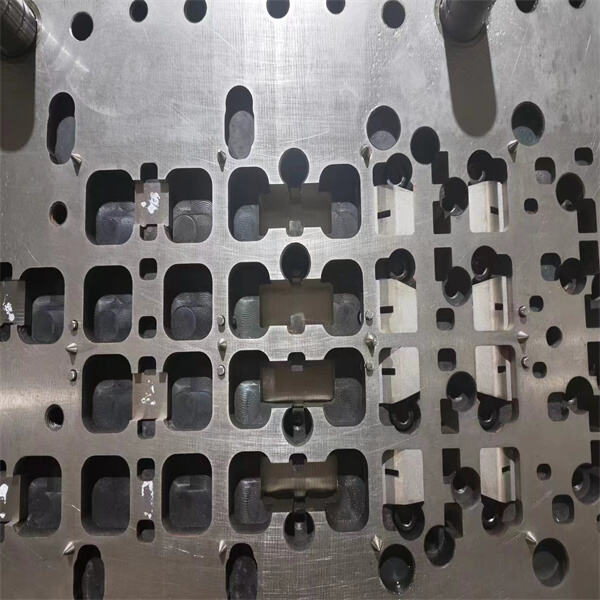

Bileşenler ve ürünler yaparken verimlilik çok kritik bir unsur. Onların daha hızlı, daha iyi çalışmasını ve bir saniye veya herhangi bir malzeme kaybetmeden istiyoruz; İlerleme damgası - Birçok şirket özellikle imalatta ilerleme damgası adında bazı araçları kullanır. Temel olarak sürekli uzunlukta ham madde parçaları kesen büyük bir damga olduğu için ilerleme damgası olarak adlandırılır. Ayrıca bu, işleri çok hızlı ve kesin yapabileceğimiz anlamına gelir ki, bunlar da üst düzeyin özellikleridir.

Burada tasarımcıların, progresif kalıpların üretim sırasında kullanımı kolaylaşması için kullanacakları birkaç ipucu ve trick bulunmaktadır. Ve evet, bir terim Modüler Tasarım'dır. Eğer gerekirse veya değiştirilebilir şekilde (ve böylece devam eder) bir kalıpta parçaları ayrıştırma fikri budur. Bir kıyaslamaya örnek vermek gerekirse, şu şekilde düşünün: eğer yoğun kullanım sonucunda kalıbın sadece bir kısmını kırarsanız veya aşındırırsanız ve sadece o kısmı değiştirilmesi gerekiyorsa her seferinde tamamen yeni bir parça yapmanıza gerek yoktur. Bu durum onlara hem zaman hem de para kazandırır ve süreci daha verimli hale getirir.

Otomasyon, burada çokça bahsedildiği gibi başka bir önemli teknik olabilir. Bu görevlerin çoğu otomatize edilmiştir (Makinalar çoğu... otomasyonu hızlı ve verimli bir şekilde gerçekleştirebilir, insan hesaplamasından bağımsız olarak, böylece insanlar kısa veya orta vadede şifrelenemeyen sayısız diğer eylemlere odaklanabilsin.) Bir işlemin makineler tarafından otomatize edilmesi, bunu daha hızlı ve o anda daha az hata ile yapmayı sağlayabilir, el ile her şeyi yapma sırasında meydana gelen birçok hatayı büyük ölçüde önleyebilir. Otomasyon demek daha hızlı, daha iyi parçalar demektir... değil mi?!

Aynı zamanda, bu ile birlikte yeni bir kavram kaydedilir - kesici laser. Laser kesici, üretimde maliyet ve zaman kazandırmaya olanak tanıyan çok hassas bir yöntemdir. Odaklanmış bir ışık ışını, dokularda çok ince kesimler yapmayı mümkün kılar. Laser kesimi, ilerlemiş matrislerle birlikte şirketlere daha önce görülmemiş şekilde çok daha karmaşık şekiller ve tasarımlar sunabilir. Yeni fırsatlar, imalat manzarası boyunca meydana gelen değişimlerin sonucudur ve icatın yapıldığından beri görmediğimiz kadar geniş bir yelpazeyi sunmaktadır.

Hızlı prototip oluşturma da çok etkileyici bir fikirdir. Kısaca, hızlı prototip oluşturma, en küçük bileşenler ve ürünler için modelleri daha hızlı oluşturmak amacıyla 3B yazıcı gibi yüksek teknolojiyi tanıtmıştır. Temel olarak bu, şirketlere prototipleri günler içinde tamamlamasını ve maliyetlerini eskiden kullandıklarının bir parçasına indirmesini sağlar. Üreticiler, fikirlerinin çalışıp çalışmadığını hızlıca test edebilirler ve bunun için birçok tane yapmaları gerekmez. Bu, pahalı hatalardan kaçınmaya yardımcı olur ve sonuçta tasarım sürecini daha verimli hale getirir.

Eğer üretim hızı istiyorsanız, bir simülasyon yazılımı en iyi yollardan biridir. Yazılım, kesimden montajına kadar her şeyi tek bir parça olarak tam üretim sürecine kadar simüle edebilir ve bu da herhangi bir gerçek parça üretilmeden önce olur. Yerel işletmeler bu teknolojiyi kullanarak sorunları anlamaya ve sistem duruşuna dönüşmeden önce bunları temel düzeyde bağımsız olarak çözebilirler. Bu, üreticilere sorunların üretim sürecinde çok ileri gitmeden önce erken tespit etme fırsatı verir, bu da sonuçta zaman ve para kazandırabilir.

Malzeme seçimi yaparken dikkatli olun, çünkü yukarıdaki faktör nedeniyle tüm malzemelerin benzersiz özelliklere sahip olması ve çeşitli ürünlerin her ikisi de puanlama üzerinde bilinir olacaktır, bu nedenle bu davranışların bir kurs boyunca nasıl davrandıklarını gösteren bazı özellikler yaşayabiliriz. Örneğin işaretlemek için iyi bir materyal seçmek, onu doğru şekilde çalışmasını ve daha uzun süre dayanmasını sağlar; Malzemelerin doğru seçimi, tüm süreçleri geliştirmekte çok önemlidir.

Telif Hakkı © Ningbo Wenzhou Technology Co.,Ltd. Tüm Hakları Saklıdır - Gizlilik Politikası