Điện thoại:+86-13777263762

Email:[email protected]

Điện thoại:+86-13777263762

Email:[email protected]

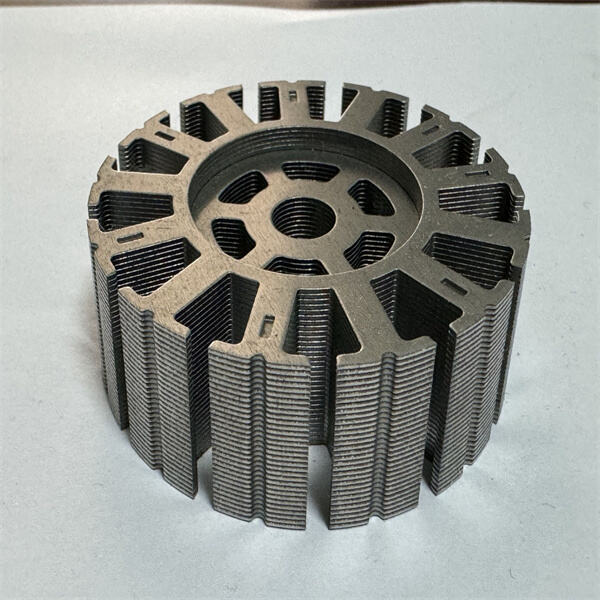

Để khởi động bất kỳ loại máy móc nào, cần một chút thời gian trước khi nó bắt đầu hoạt động. Động cơ: Một động cơ cung cấp lực đẩy này. Hai thành phần chính cấu thành bên trong động cơ là stato và rôto. Stato: Phần tĩnh không di chuyển và Rotor là phần của động cơ. Hai phần này rất quan trọng vì không có chúng, máy móc không thể hoạt động.

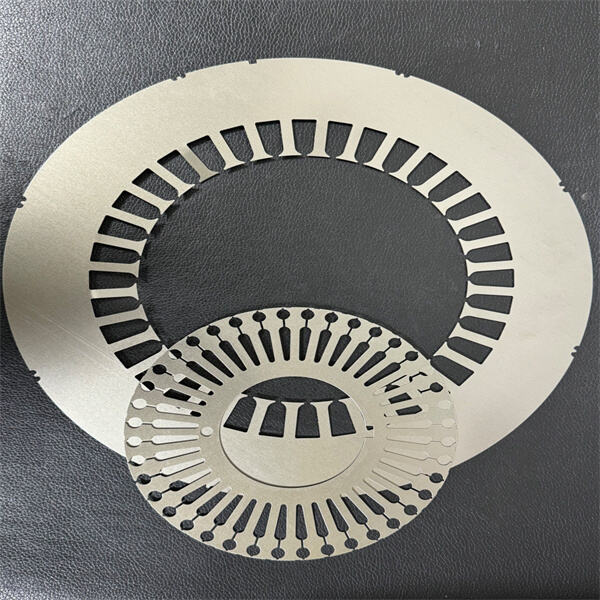

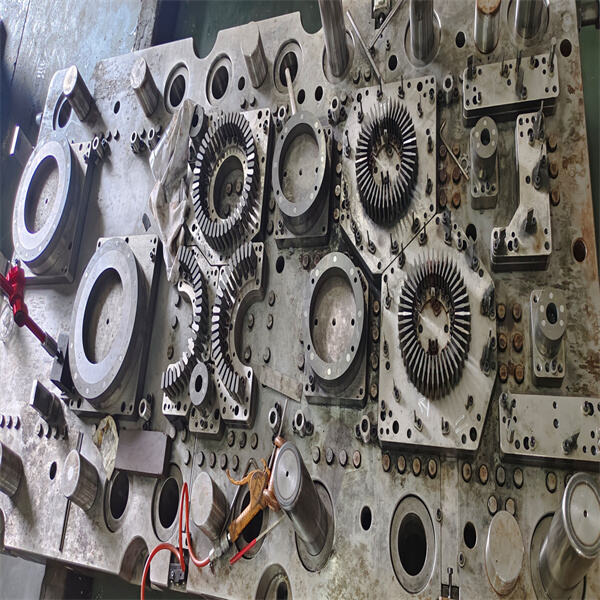

Các khuôn được thiết kế để phù hợp với các bộ phận stato và rôto mới của động cơ. Ngoài ra, các nhà máy có khuôn cũng có các công cụ chuyên dụng được chế tạo dành riêng cho CÁC PHẦN STATO VÀ RÔTO ĐỘNG CƠ MỚI ĐỂ SỬ DỤNG THEO YÊU CẦU. Các khuôn cũng giống như một "bộ cắt bánh quy", chúng giữ các bộ phận ở trạng thái và độ chính xác đúng đắn. Điều này đảm bảo rằng tất cả các bộ phận động cơ khi sử dụng, ví dụ được ép khuôn, sẽ có hình dạng đặc trưng mà các nhà thiết kế đã giả định. Điều này giúp các máy móc hoạt động hiệu quả hơn, dẫn đến tốc độ nhanh hơn và hoạt động mượt mà hơn tổng thể.

Trước đây, các bộ phận động cơ phải được chế tạo bằng tay, điều này thường mất rất nhiều thời gian. Mặc dù tham khảo phần trên, phương pháp này có thể thường thất bại vì việc tạo ra các ứng dụng của bạn không hiệu quả như khi bạn mắc lỗi. Nhưng bằng cách sử dụng khuôn stato và rôto trong một quy trình mới, việc sản xuất các bộ phận này đã trở nên cực kỳ dễ dàng và hoàn hảo hơn chúng ta từng tưởng tượng.

Bằng cách sử dụng khuôn, các nhà máy có thể sản xuất một số lượng lớn các bộ phận động cơ cùng một lúc. Nó trở thành một quá trình sản xuất hàng loạt. Có vẻ như sản xuất hàng loạt là tốt vì nó tiết kiệm thời gian và thậm chí cả chi phí. Nó cũng cho phép sửa chữa máy móc dễ dàng hơn nếu một bộ phận bị hỏng. Melfi nói rằng khuôn có thể tạo ra các bộ phận giống hệt nhau mỗi lần, vì vậy các nhà máy sẽ luôn có sẵn một bộ phận nhất định khi họ cần.

abcxyzNếu bạn muốn giỏi về cắt chuyên sâu, một số máy cũng cần một loại phần tử khác abcxyzeniam giúp cải thiện hiệu suất tốt hơn. Các nhà máy có thể tạo khuôn hoặc rotor và stator tùy chỉnh để trộn khi sản phẩm tiêu chuẩn không đủ. Khuôn tùy chỉnh cũng rất hữu ích vì đó là cách để các máy này hoạt động tốt nhất và trong một số trường hợp, nó làm cho chúng bền hơn.

Trong nhiều trường hợp, điều đó có thể có nghĩa là tạo ra một khuôn để giữ máy hoặc các bộ phận đầu ra để nó sử dụng trong những hoàn cảnh cụ thể. Điều này làm cho máy mạnh mẽ và đáng tin cậy khi sử dụng ở mức độ cao. Khuôn tùy chỉnh cho phép các dây chuyền sản xuất của nhà máy tạo ra các bộ phận với nhiều kích thước và hình dạng khác nhau từ cùng một máy.

Một số máy móc sử dụng các bộ phận như động cơ sẽ được sản xuất bằng khuôn, điều này rất hữu ích cho việc hoạt động của máy móc vì nếu phần thịt trông nặng và lớn, trong trường hợp đó sẽ không cần thiết phải có sự lãng phí ở đây. Sử dụng khuôn nghĩa là tất cả các bộ phận đều ra đời hoàn hảo, điều này cải thiện hiệu suất chung của máy móc. Điều đó có nghĩa là với việc sử dụng trí tuệ nhân tạo, máy móc có thể vận hành một cách hiệu quả hơn trong thời gian dài hơn.

Bản quyền © Công ty Công nghệ Ninh Ba Ôn Châu. Tất cả các quyền được bảo lưu. - Chính sách bảo mật