Điện thoại:+86-13777263762

Email:[email protected]

Điện thoại:+86-13777263762

Email:[email protected]

Bạn có biết rằng chiếc xe hơi là một sản phẩm không? Nó thật sự rất thú vị! Theo GM, xe hơi được chế tạo thông qua một quy trình gọi là dập kim loại. Quy trình này bao gồm việc sản xuất các tấm kim loại lớn từ đầu, sau đó cắt và khắc các tấm thành các bộ phận riêng lẻ của xe: ví dụ như cửa hoặc động cơ[5]. Cũng cần nhấn mạnh rằng việc sản xuất các bộ phận kim loại không hề đơn giản. Đây thực chất là kỹ thuật chính xác. Nghĩa là, tất cả phải được đo lường và cắt chính xác, nếu không chúng sẽ không khớp với nhau như một câu đố.

Các công ty sử dụng vật liệu chất lượng cao và kỹ thuật độc đáo để sản xuất các bộ phận nhằm tạo ra hộp số xe hơi tiên tiến hơn. Tôi muốn nói rằng trong những tình huống cụ thể, một số loại thép thực sự rất bền và cực kỳ quan trọng đối với an toàn, ví dụ như kính chắn gió. Các lớp phủ chỉ đại diện cho độ rộng của một đường sọc (B60), nhưng chúng giúp ngăn ngừa bề mặt kim loại bị gỉ và ăn mòn. Lợi ích của tuổi thọ linh kiện ô tô. Ép sâu là phương pháp mà họ đôi khi sử dụng, thay vì chỉ đóng dấu lên tấm kim loại. Được gọi là tạo hình tấm, phương pháp này sử dụng lực để kéo một tấm kim loại mỏng vào hình dạng phức tạp gần giống như cách đất sét có thể được định hình trên bàn xoay. Ưu điểm lớn nhất của phương pháp này là tạo ra các bộ phận được thiết kế tỉ mỉ phù hợp với chiếc xe.

Việc tạo ra những phụ tùng ô tô độc đáo này có thể rất tốn kém và mất nhiều thời gian. Đó là lý do các công ty liên tục tìm kiếm cách để tiết kiệm chi phí và làm việc hiệu quả hơn. Một cách thông minh mà họ làm điều này là thông qua mô phỏng bằng máy tính. Nhờ những mô phỏng này, họ có thể khám phá các thiết kế khác nhau trước khi hoàn thiện các bộ phận. Điều này cho phép họ xác định cách tốt nhất và kinh tế nhất để cắt tấm kim loại, dẫn đến việc tiết kiệm đáng kể theo thời gian. Các thiết bị tiên tiến cũng được sử dụng có thể nhanh chóng và chính xác dập các bộ phận cần thiết để đảm bảo sản xuất diễn ra đúng tiến độ.

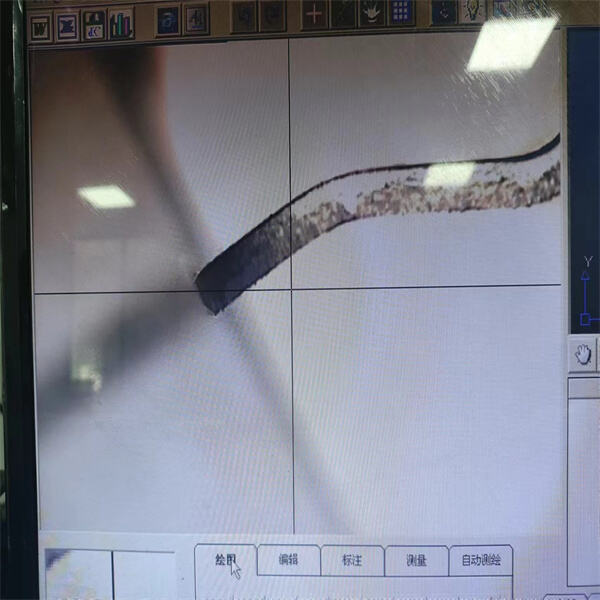

Mặc dù những phương pháp này thông minh, việc tạo ra các bộ phận kim loại đáng tin cậy và chất lượng tốt cho ô tô vẫn là một nhiệm vụ khó khăn. Ở đây có sự tài năng và công sức cần thiết. May mắn thay, công nghệ mới đang giúp các công ty sản xuất ra những bộ phận mạnh mẽ hơn, nhẹ hơn và tốt hơn ở mọi khía cạnh so với trước đây. Ví dụ, một số nhà sản xuất hiện nay cắt tấm kim loại bằng tia laser. Công nghệ này cho phép họ thiết kế các cạnh sắc cực kỳ chính xác của các bộ phận, điều này rất quan trọng cho việc ghép nối chúng. In 3D cũng đang được một số công ty khác sử dụng để sản xuất khuôn mẫu và nguyên mẫu. Điều này cũng cho phép họ thử nghiệm các thiết kế và vật liệu mới trước khi đưa vào sản xuất hoàn toàn.

Việc sản xuất phụ tùng ô tô tùy chỉnh cho các thương hiệu khác nhau là một trong những yếu tố quan trọng nhất trong công nghệ dập kim loại. Điều này có nghĩa là họ phải sản xuất các bộ phận chỉ dành riêng cho các mẫu xe cụ thể, ví dụ như Honda Civic hoặc Toyota Camry. Mỗi loại xe đều có những yêu cầu khác nhau và việc tạo ra các bộ phận phù hợp hoàn hảo với những nhu cầu đó là điều then chốt đối với sự an toàn và hiệu suất của phương tiện của bạn. Trong một số trường hợp, các công ty đã đi xa hơn bằng cách hợp tác với nhà sản xuất ô tô trong việc thiết kế và thử nghiệm các bộ phận mới. Những mối quan hệ hợp tác này đảm bảo rằng các linh kiện sẽ hoạt động hoàn hảo và loại bỏ mọi nghi ngờ về vấn đề an toàn.

Bản quyền © Công ty Công nghệ Ninh Ba Ôn Châu. Tất cả các quyền được bảo lưu. - Chính sách bảo mật