Điện thoại:+86-13777263762

Email:[email protected]

Điện thoại:+86-13777263762

Email:[email protected]

Nhà máy sử dụng các khuôn đục và khuôn dập, đây là những công cụ đặc biệt để tạo ra các sản phẩm kim loại. Các công cụ và thiết bị này cực kỳ quan trọng vì chúng cho phép con người lấy kim loại thô, cắt nó, thay đổi hình dạng của nó và chuyển đổi cấu trúc của vật liệu này thành một hình thức hoàn toàn khác, sẵn sàng để sử dụng trong một số lượng lớn các sản phẩm khác nhau. Dù là phụ tùng ô tô, vật liệu xây dựng hay nhiều đồ dùng hàng ngày khác.

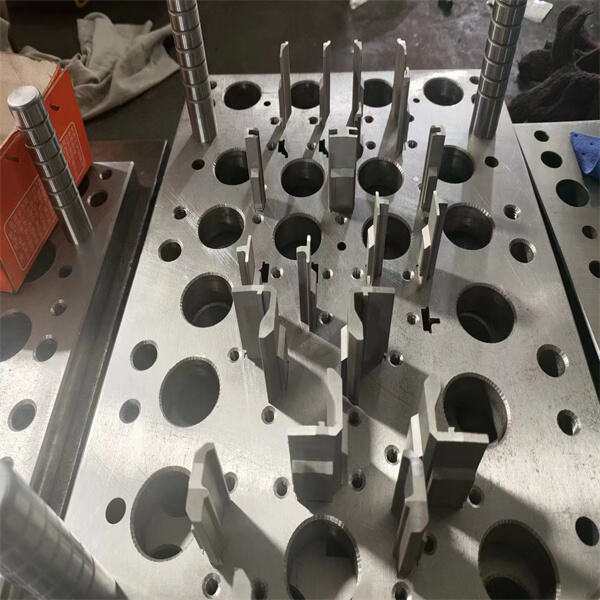

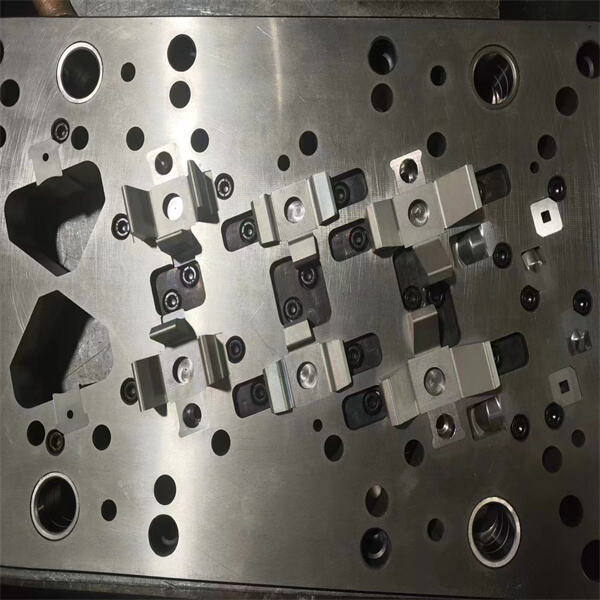

Bạn cũng phải chuẩn bị bằng cách làm các đục kim loại và khuôn từ những vật liệu đủ mạnh để hấp thụ áp lực này, ví dụ như chúng tôi đã sử dụng Nylatex (nylon) rất hiệu quả làm đục khi đục vàng mềm. Một con đục là một mảnh kim loại hình trụ hoặc phẳng, có một đầu được tạo hình theo dạng mong muốn. FAB này đôi khi được gọi là MŨI TIÊM vì đầu nhọn của nó cho phép đục được đưa vào kim loại và tạo ra các lỗ hoặc hình dạng đặc biệt. Mặt khác, một khuôn là một loại công cụ dùng trong việc định hình kim loại (hoặc bất kỳ vật liệu nào khác), trong đó nó tạo hình bằng cách áp dụng lực để ép vật liệu vào hình dạng đã định sẵn thông qua bề mặt khuôn. Và cho mục đích này, một khuôn được sử dụng có hình dạng chính xác cho phép dòng chảy của thép đi vào đó và lấy hình dạng của đường thẳng.

Bộ phận đục lỗ và khuôn đục có nhiều hình dạng khác nhau, điều này làm cho việc gia công kim loại trở nên thú vị hơn! Chẳng hạn như: Đục lỗ tròn, đục lỗ vuông và đục lỗ phẳng. Khi cần khoan lỗ trên kim loại (thường là hình tròn), các dụng cụ tròn sẽ được yêu cầu. Đục lỗ vuông có thể được sử dụng để tạo cả lỗ đơn (loại lỗ 2) và lỗ hình chữ nhật. Đục lỗ phẳng - bạn có thể sử dụng chúng để cắt hoặc tạo hình bề mặt kim loại phẳng. Do đó, chúng rất phù hợp để sử dụng trong nhiều ứng dụng gia công kim loại khác nhau.

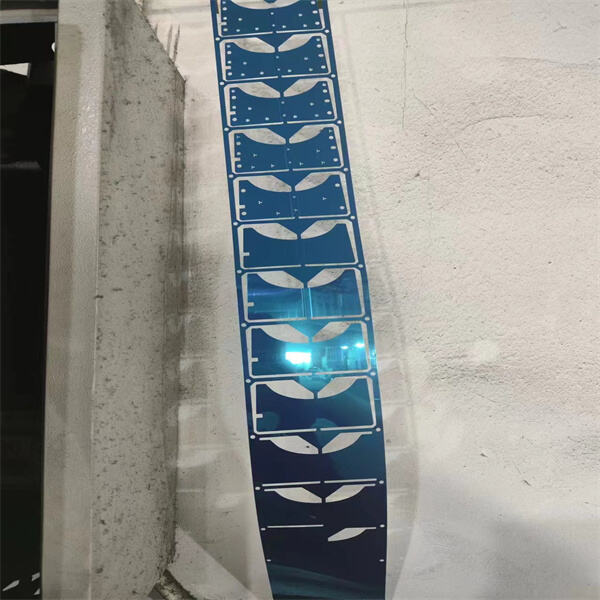

Việc chế tạo một số hình dạng hoặc hoa văn trên kim loại yêu cầu các thiết kế đặc biệt, cụ thể là các công cụ đột và dập kim loại tùy chỉnh được sử dụng. Việc sản xuất những sản phẩm chuyên dụng này được hỗ trợ nhờ vào các công cụ này, mà không thể sản xuất thủ công bằng máy móc thông thường. Điều này có thể liên quan đến việc một nhà sản xuất sử dụng các thiết kế, trong đó có thể sử dụng đột hoặc dập tùy chỉnh (tùy thuộc vào trường hợp) - mandrel duy nhất phù hợp cho sản phẩm mục tiêu, nếu điều này khả thi. Và điều này cũng giúp ngăn ngừa lãng phí, tiết kiệm thời gian và tiền bạc về lâu dài vì các công cụ tùy chỉnh sẽ vừa khít với yêu cầu, do đó sẽ không có nhiều vật liệu bị lãng phí hoặc không cần phải lặp lại quy trình nếu lần đầu thực hiện không chính xác.

Một bộ đấm và khuôn là tuyệt vời để cắt kim loại theo cách chính xác mà không làm biến dạng vật liệu tấm. Đó là lý do với sự hỗ trợ từ thiết bị này, bạn có một kế hoạch toàn diện thể hiện hệ thống bên cạnh đó giúp tạo ra các công việc có chi tiết cao và hình dạng phức tạp. Khả năng điều chỉnh đơn giản cũng là một trong những đặc điểm được yêu thích nhất của bộ đấm và khuôn. Điều này cho phép bạn điều chỉnh cài đặt hoặc sử dụng công cụ khác phù hợp hơn với bất kỳ hình dạng nào khác.

Từ những năm 1950 đến ngày nay, các công cụ đột và dập kim loại tạo thành một phạm trù rộng lớn của công nghệ giúp duy trì hoạt động của các nhà máy. Chúng đã được ứng dụng mạnh mẽ trong sản xuất ô tô, xây dựng; thậm chí các bộ phận của một chiếc máy bay cũng được chế tạo bằng cách sử dụng hợp chất sợi carbon. Facebook Những đoạn kể trên minh họa rõ ràng mức độ linh hoạt thực sự của các công cụ này. Các công cụ đột và dập cho phép nhà máy vận hành với tốc độ chóng mặt, hầu như không lãng phí nguyên liệu (điều này có thể nói là hiệu quả nhất). Điều này cho phép họ sản xuất nhiều sản phẩm hơn trong thời gian ngắn hơn, đảm bảo rằng họ có thể đáp ứng nhu cầu.

Bản quyền © Công ty Công nghệ Ninh Ba Ôn Châu. Tất cả các quyền được bảo lưu. - Chính sách bảo mật