Điện thoại:+86-13777263762

Email:[email protected]

Điện thoại:+86-13777263762

Email:[email protected]

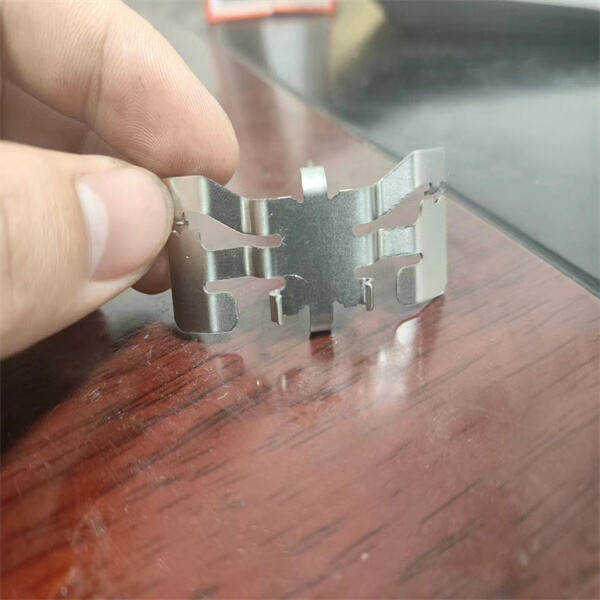

Việc dập kim loại không chỉ mang tính nghệ thuật mà còn cung cấp một phương pháp độc đáo để tạo hình hoa văn trên các tấm nhôm. Điều này có nghĩa là sử dụng một khuôn (giống như con tem) và một máy ép thủy lực, một chiếc máy khổng lồ kết hợp cả hai phần lại với nhau - theo cách nói dễ hiểu hơn. Máy ép này được sử dụng để cắt và uốn cong nhôm thành các hình dạng mong muốn. Đây là một phương pháp tuyệt vời để tạo ra các bộ phận giống hệt nhau và đảm bảo chúng trông đẹp khi bạn nhận được chúng.

Việc gia công nhôm là một kỹ năng mà nhiều người đã từng sử dụng để làm trong quá khứ, nó rất tuyệt và độc đáo. Nó liên quan đến việc nhà sản xuất tạo hình và chi tiết hóa sản phẩm bằng cách sử dụng khuôn kim loại, sau đó ép chúng với nhiệt độ cao lên các bộ phận nhựa được thiết kế chính xác, từ đó các bộ phận đó được sản xuất ra. Đó là sự thực hành, tập trung đúng đắn và chú ý đến chi tiết có thể giúp bạn đạt được chất lượng tuyệt vời của phần nhôm. Khi nói đến việc dập kim loại, sự chú ý và chính xác là điều bắt buộc.

Đối với các doanh nghiệp đang tìm cách sản xuất các bộ phận hoàn hảo, việc dập nhôm là một lựa chọn phù hợp. Cơ sở này đơn giản cho phép các nhà sản xuất tạo ra sự khớp về yếu tố hình thức giống hệt nhau. Điều này rất quan trọng trong đảm bảo chất lượng vì nó đảm bảo tính nhất quán qua nhiều kích thước và hình dạng khác nhau từ các đợt sản xuất khác nhau. Dập kim loại sẽ giúp bất kỳ công ty nào có thể sản xuất được số lượng linh kiện cần thiết hoặc chỉ vài bộ phận mà họ cần cho doanh nghiệp của mình.

Việc dập kim loại nhôm có thể cung cấp các bộ phận nhôm mỏng, có độ bền cao. Những vật thể này có nhiều lợi thế và được sử dụng trong nhiều ứng dụng khác nhau như ô tô, máy bay, laptop và hơn thế nữa. Quy trình này mang lại cho các công ty tùy chọn sản xuất các bộ phận được thiết kế theo đúng thông số kỹ thuật của họ để chúng hoạt động chính xác như mong muốn.

Đánh Dấu Kim Loại Với Nhôm: Tại Sao Lựa Chọn Nó? Thứ nhất, nhôm nhẹ và chắc chắn, điều này có nghĩa là nó có thể chịu được một số tác động mà không bị biến dạng. Đây là một quy trình tiết kiệm chi phí và cũng là cách tốt nhất để sản xuất các bộ phận với giá thấp hơn, giúp các công ty đánh dấu kim loại ở Úc tiết kiệm tối đa bằng cách sản xuất những sản phẩm chất lượng cao hơn. Thứ ba, đây là một quy trình nhanh chóng và thuận tiện, cho phép công ty tạo ra nhiều bộ phận trong thời gian ngắn.

Bởi vì bạn có thể sản xuất một tấm nhôm mỏng hơn với trọng lượng tương ứng nhẹ hơn, điều này làm cho các bộ phận này có sẵn cho hầu hết mọi ngành công nghiệp và ứng dụng. Đánh dấu kim loại là một trong những phương pháp hiệu quả nhất để lắp ráp các bộ phận chi tiết và chính xác. Đánh dấu kim loại cho phép các công ty xem xét các khái niệm thiết kế mới và khả năng mà không thể được sản xuất thông qua các kỹ thuật sản xuất truyền thống.

Việc dập kim loại mang lại lợi ích ở chỗ nó giữ cho lượng phế liệu ở mức tối thiểu. Các công ty có thể sản xuất chỉ số lượng linh kiện mà họ cần nên có ít lãng phí hơn. Phương pháp này còn sử dụng một lượng năng lượng thấp hơn, tốt hơn cho Trái đất và do đó giảm dấu chân carbon so với bất kỳ quy trình nào khác ngoài sản xuất. Do đó, cả hai yếu tố này khiến việc dập kim loại nhôm trở thành một lựa chọn tuyệt vời cho các công ty muốn chuyển sang các giải pháp thân thiện với môi trường hơn.

Bản quyền © Công ty Công nghệ Ninh Ba Ôn Châu. Tất cả các quyền được bảo lưu. - Chính sách bảo mật