Điện thoại:+86-13777263762

Email:[email protected]

Điện thoại:+86-13777263762

Email:[email protected]

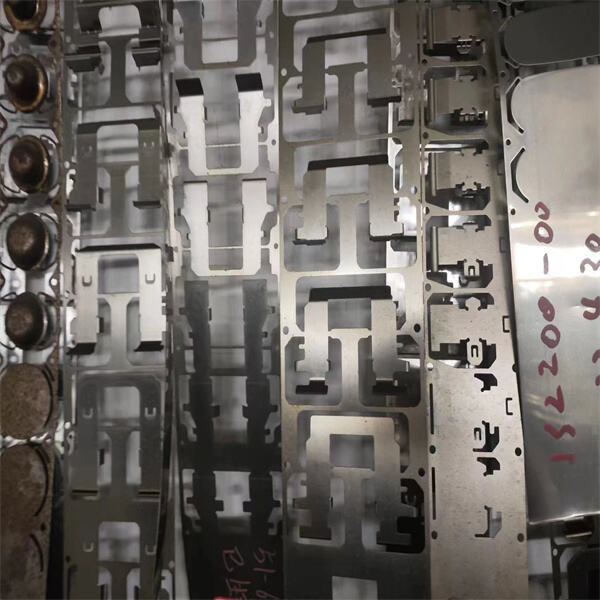

Đánh dấu kim loại là một quy trình thú vị để tạo hình kim loại thành các đối tượng khác nhau. Sử dụng đấm và khuôn, phương pháp này chuyển đổi các tấm kim loại thành nhiều đối tượng khác nhau, từ nắp capô ô tô đến xe đồ chơi hoặc các bộ phận trang sức phức tạp.

Vật liệu và Thiết bị Đánh Dấu Kim Loại Có nhiều bộ phận và công cụ khác nhau được sử dụng để làm việc trên kim loại khi Đánh Dấu Kim Loại, quá trình làm việc với các ứng dụng. Thép, Nhôm và Đồng là những vật liệu được sử dụng thường xuyên nhất để sản xuất các sản phẩm đúc đầu tư vì mỗi loại đều có đặc điểm riêng ảnh hưởng đến tính chất của sản phẩm. Các công cụ như đấm, khuôn và máy ép được sử dụng để tạo hình chính xác và chính xác các tấm kim loại có hình dạng nông.

Điều quan trọng là mỗi bộ phận phải đáp ứng các thông số kỹ thuật thiết kế và yêu cầu mạnh mẽ này phải được thực hiện thông qua các quy trình đánh dấu kim loại chính xác và đáng tin cậy một cách liên tục. Bằng cách sử dụng các vật liệu chất lượng tốt, nhà sản xuất có thể đảm bảo rằng các đặc tính của kim loại luôn ổn định và theo một lộ trình tương tự. Việc sử dụng các công cụ và máy móc chính xác trong quá trình tạo hình có thể tạo ra các sản phẩm có hình dạng chính xác và kích thước nhỏ hơn để tránh sự không đồng đều trong đầu ra cuối cùng.

Cách Đánh Dấu Kim Loại Có Thể Biến Đổi

Với sự cải thiện về chất lượng và hiệu suất của các sản phẩm, điều này cũng cho phép tạo ra những thiết kế phức tạp hơn, trông ấn tượng về mặt thị giác, điều mà có thể không xảy ra với các loại sản xuất khác. Điều này cho phép tạo ra những hình dạng và thiết kế phức tạp hơn cho các sản phẩm, mang lại cho chúng một cảm giác đặc biệt; từ đó làm nổi bật tính thẩm mỹ hoặc khiến nó trở nên thu hút về mặt thẩm mỹ.

Ép kim loại là một phần quan trọng trong sản xuất hiện đại và hỗ trợ các nhà sản xuất mở rộng khả năng của họ. Được áp dụng sáng tạo với nhiều quy trình ép khác nhau, các nhà sản xuất có thể tăng cường độ bền và độ tin cậy (chưa kể đến ngoại hình) của sản phẩm của họ, điều này sẽ thu hút mạnh mẽ cả người tiêu dùng ở mọi cấp độ. Hơn nữa, việc ép kim loại còn tăng hiệu quả, cải thiện tốc độ mà các nhà sản xuất có thể đưa sản phẩm đến tay người tiêu dùng; đây là một tình huống đôi bên cùng có lợi cho cả ngành công nghiệp lẫn người tiêu dùng.

Vậy, tóm lại, dập kim loại cho phép nghệ sĩ trở nên rất năng động và sáng tạo trong cách họ tạo hình các đối tượng từ lưới kim loại thành những thứ vừa có tính thực dụng vừa đẹp về mặt thẩm mỹ. Về hiệu suất, nó cung cấp một chiều hướng mới. Những tài liệu tham khảo này cung cấp hướng dẫn cho các nhà sản xuất để cải thiện hiệu suất sản phẩm thông qua việc sử dụng các phương pháp, vật liệu và công cụ phụ trợ khác nhau, cuối cùng dẫn đến một môi trường sản xuất tiến bộ hơn nhờ sự đổi mới. Đây là lý do tại sao dập kim loại, với tất cả những lợi thế và lợi ích của nó, thực sự trở thành một công cụ quan trọng trong việc sản xuất các sản phẩm kết hợp giữa tính năng sử dụng và vẻ đẹp thẩm mỹ thành một.

Bản quyền © Công ty Công nghệ Ninh Ba Ôn Châu. Tất cả các quyền được bảo lưu. - Chính sách bảo mật