Tel.:+86-13777263762

E-Mail:[email protected]

Tel.:+86-13777263762

E-Mail:[email protected]

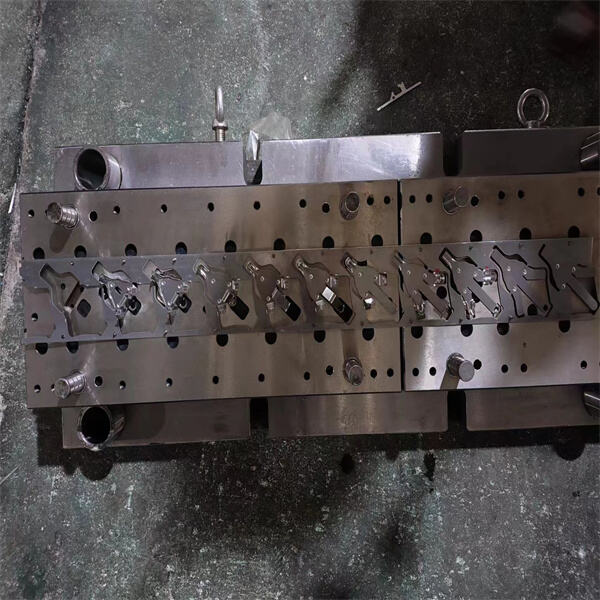

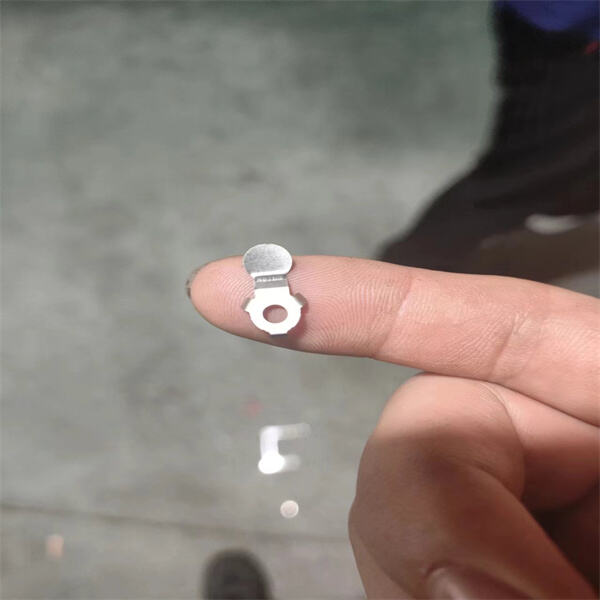

Ein Zusammengesetztes Schneidwerkzeug ist ein einzigartiges Werkzeug, das dazu gedacht ist, verschiedene Formen aus flachem Material herauszuschneiden. Dies ist ein einzigartiges Werkzeug, da es zwei oder mehrere Punch-Teile hat. Durch eine Technik, die sie alle bei derselben Einstellung bohrt, was in vielen Fällen sehr hilfreich ist, können diese Punches gemeinsam verschiedene Formen schneiden. Zusammengesetzte Schneidwerkzeuge werden häufig in der Fertigung eingesetzt, wo viele andere Gegenstände, wie Autoteile oder elektronische Geräte, ein Zusammengesetztes Schneidwerkzeug verwenden. Es wird benötigt, um alles einfacher und schneller zu machen. Aufgrund der Art und Weise, wie die Punches aufgestellt sind, können sie alle unterschiedliche Formen schneiden – mehrere gleichzeitig. Die Werkzeuge bestehen aus einem oberen und einem unteren Teil, die an einer Pressmaschine befestigt sind. Das Material wird dann auf die Presse gelegt und wenn sie aktiviert wird, hält der Druck die Teile fest, während Formen herausgeschnitten werden, die benötigt werden.

Aber es gibt so viele Vorteile bei der Verwendung von Verbundstanzwerkzeugen, dass die Fertigung auf keine andere Weise verbessert werden kann. Es hat die Fähigkeit, mehrere Formen gleichzeitig zu schneiden, was ein offensichtlicher Vorteil ist. Dies ermöglicht eine erhebliche Reduktion der Arbeitskosten und menschlichen Ressourcen, da Mitarbeiter das Material nicht bearbeiten müssen. Eine größere Effizienz des Arbeiters beschleunigt die Massenproduktion insgesamt. Eine weitere Kosteneinsparung durch diese Art der Schneidung besteht darin, dass man ein Verbundstanzwerkzeug verwenden kann, anstatt für jede Form spezielle Werkzeuge zu benötigen. Das bedeutet weniger Geld, das an Werkzeuglieferanten fließt, und für die meisten Unternehmen ist das enorm. Sie erstellen auch sehr präzise Fortschritte in der Kunst, was bedeutet, dass die Endprodukte hohe Qualität aufweisen. Und diese Toleranzen sind kritisch, insbesondere für Teile, die andere Komponenten korrekt beherbergen müssen.

Es erfordert viel Nachdenken und Planung, um eine Verbundpresse zu erstellen. Problemlösung ist keine schnelle Sache, die man ohne Nachzudenken ausführen kann. Nun wissen Sie bereits, welche Formen Sie schneiden möchten und wie viele Schläge benötigt werden. ALS NÄCHSTES kommt dieser SCHritt, DER SEHR WICHTIG IST, DA ER DIE GRUNDLAGEN DES GANZEN PROZESSES LEGT. Danach müssen Sie die Reihenfolge der Schläge in der Presse bestimmen. Sie sollten so angeordnet sein, dass der maximale Materialnutzen erzielt wird, während gleichzeitig der minimale Abfall produziert wird. Die Faustregel lautet: Materie darf nicht verschwendet werden, da dadurch Kosten steigen und die Effizienz sinkt. Noch wichtiger ist, dass Sie auch berücksichtigen sollten, wie die Schläge ausgeführt werden. Damit wird ein reibungsloser und effizienter Schnitt unterstützt. Abschließend notieren Sie sich Größe und Dicke des Materials, das Sie verwenden, um sicherzustellen, dass es mit Ihrer Presse die Formen effektiv schneiden kann.

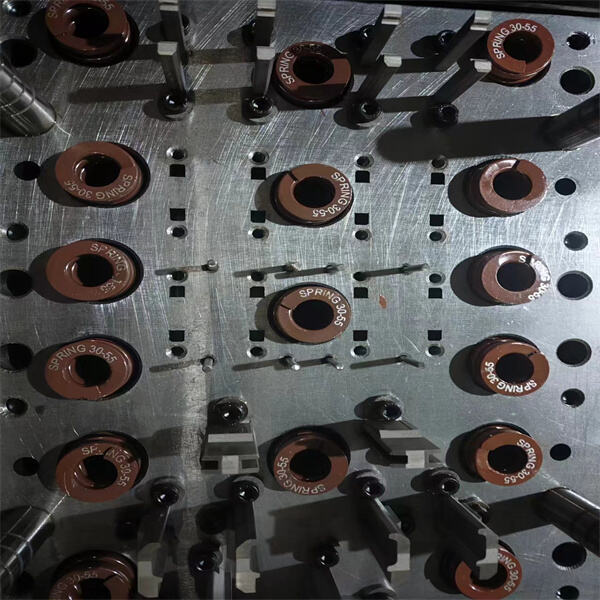

Aber trotz der Vorteile des kombinierten Locher- und Schneidens kann es auch Probleme geben. Die Löcher können recht schnell stumpf werden. Das Problem ist, je stumpfer sie sind (gesehenen Schäden an nicht allzu alten Teilen), desto schlechter schneiden sie, sodass die Kanten an den Schnitten weniger definiert sein werden. Die Schablonen sollten häufig überprüft und getragenete Teile ersetzt werden, um dieses Problem zu beheben. Diese Wartung ist essenziell, um die Schablone gut funktionierend zu halten. Die Löcher könnten sich außerdem im Material festsetzen, was ein weiteres Problem verursacht. Wenn dieses Festsetzen in den Zahnradverbindungen auftritt, können sich die Kanten ändern oder einige Fasern/Teppiche können beeinflussen, wie genau sie schneiden. Regelmäßige Reinigung der Löcher kann helfen, dies zu verhindern und Dinge reibungslos laufen zu lassen. Abschließend könnte es sein, dass falsche Einstellungen den Grund für fehlerhaftes Schneiden sind. Effizientes Schneiden und sicherstellen, dass alles korrekt geschnitten wird, erfordert die richtige Einstellung aller Parameter.

Ein Zusammengesetzter Stanzwerk muss gut gewartet werden, damit es gut funktioniert und länger hält. Reinigen und überprüfen Sie die Stanzwerk-Teile regelmäßige Intervalle, um Verschleiß zu verhindern. Sie müssen regelmäßige Wartungen durchführen und sollten potenzielle Probleme früh erkennen können. Ersetzen Sie verschlissene oder beschädigte Komponenten sofort, um keine zusätzliche Belastung auf das Gesamtsystem auszuüben. Die Schmierung der beweglichen Teile minimiert auch Reibung und kann die Lebensdauer des Stanzwerks erhöhen. Dies ist entscheidend, da es einen reibungslosen Betrieb sicherstellt. Abschließend müssen Sie das Stanzwerk ordnungsgemäß lagern und behandeln, damit kein Schaden entsteht. Selbst bei richtiger Lagerung und vorsichtigem Umgang hat ein Stanzwerk nur eine begrenzte Anzahl von Umdrehungen in seiner Struktur.

Copyright © Ningbo Wenzhou Technology Co., Ltd. Alle Rechte vorbehalten - Datenschutzrichtlinie