Tel.:+86-13777263762

E-Mail:[email protected]

Tel.:+86-13777263762

E-Mail:[email protected]

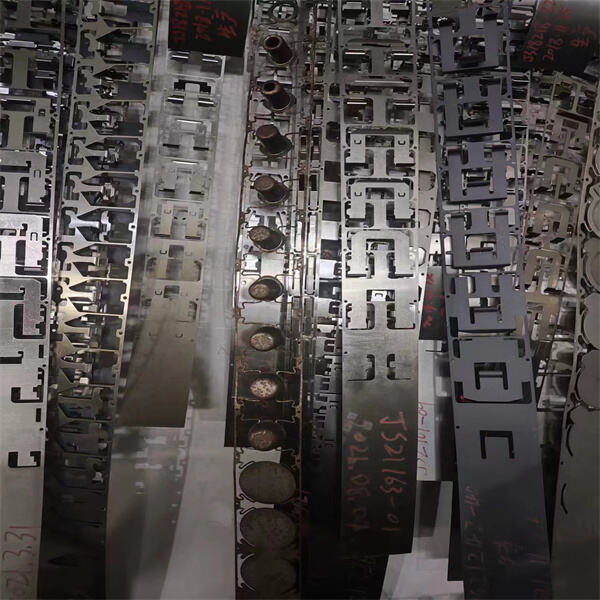

Wie oft haben Sie auch schon kleine, glänzende Metallstücke in einer Maschine, einem Spielzeug oder sogar in Ihrem Fahrrad gesehen? Wenn ja, ist es wahrscheinlich, dass sie mit einem einzigartigen Prozess namens Progressiver Stampf hergestellt wurden. Diese Technik umfasst das Durchziehen, Biegen und Formen von Metallplatten mit einem individuellen Design unter Verwendung fortschrittlicher Werkzeuge. Es ist ein faszinierender Prozess, der dazu beiträgt, viele der Gegenstände zu formen, die wir täglich verwenden. Zuerst jedoch ein wenig darüber, warum dieser Prozess so spannend und gleichzeitig wichtig ist!

Geschwindigkeit der Produktion: Einer der bemerkenswertesten Vorteile des fortschreitenden Stanzens ist, wie es zur schnelleren Erstellung von Teilen beiträgt. Damit konnten Hersteller viele identische Stücke gleichzeitig massenweise produzieren. Dies ist wichtig, da es Zeit und Geld spart. Mit weniger Maschinen und Arbeitern, die benötigt werden, summieren sich die Kosten, so dass die Produktion in einem beschleunigten Tempo vorankommen kann!

Ein weiterer Vorteil ist, dass Teile, die durch Progressive Die Stamping hergestellt werden, im Allgemeinen eine konsistente und zuverlässige Qualität aufweisen. Diese Maschinen schneiden und formen sehr genau, was für einen Menschen fast unmöglich ist. Dadurch können die Teile etwas besser zusammenarbeiten und ihre Aufgabe effektiver erfüllen.

Während das Metallblech durch diese hochgeschwindigte und leistungsstarke Maschine gleitet, arbeiten die obere Hälfte der Presswerkzeuge in Koordination mit dem unteren, stationären Bett, um das entsprechende Teil zu schneiden/formen/umzubilden. Während des Prozesses wirst du verschiedene Werkzeuge verwenden, um langsam dein endgültiges Design aufzubauen. Es ist ein langsamer Prozess, aber ich muss ihn in meinem eigenen Tempo durchführen, damit jedes kleine Detail perfekt ist.

Fortschreitendes Sterzen und Präzision Gewährleistung dass die fertigen Teile robust und gut im Finish sind. Kleine Fehler in der Stahlschneidphase oder -formphase können sich zu erheblichen Problemen bei der Endproduktionsphase auswachsen. Wenn die Teile nicht richtig passen, können sie zu Fehlfunktionen führen.

Diese Präzision wird durch spezielle Computerprogramme erreicht, die die Blechmetall-tormakines und Schnitte entwerfen. Sie verwenden auch sehr genaue Meßinstrumente, um sicherzustellen, dass jedes Teil genau so hergestellt wird, wie es sollte. Dieses Maß an Präzision ist der Grund, warum fortschreitende Sterz-Werkstätten so erfolgreich sind.

Die Auswahl der richtigen Materialien ist auch entscheidend, um die Stärke und einen längeren Lebenszyklus der hergestellten Teile zu gewährleisten. Eine Vielzahl von Anwendungen wird durch einen breiten Spektrum an Metallen und Legierungen bedient, wobei jedes seine eigenen Eigenschaften aufweist, die sie in verschiedenen Kontexten nutzbar machen. Stahl: Stahl wird aufgrund seiner besseren Eigenschaften wie Stärke und Verschleißwiderstand, die in Arbeitskomponenten oft benötigt werden, regelmäßig verwendet. Diese sind am besten für anspruchsvolle Verwendungen geeignet.

Copyright © Ningbo Wenzhou Technology Co., Ltd. Alle Rechte vorbehalten - Datenschutzrichtlinie