Telp:+86-13777263762

Email:[email protected]

Telp:+86-13777263762

Email:[email protected]

Pernahkah Anda bertanya-tanya bagaimana perangkat elektronik favorit Anda, seperti ponsel pintar dan tablet dibuat? Itu sangat menarik! Salah satu alat penting yang memainkan peran besar dalam proses ini adalah Terminal Stamping Mold. Terminal-terminal tersebut adalah bagian kecil logam yang dibentuk oleh mesin khusus ini. Bagian-bagian kecil ini memiliki nilai dan penting besar karena resistor-resistor ini hanya membantu eksekusi yang tepat dari alat listrik. Komponen-komponen ini sebenarnya hanyalah manipulasi bagian logam kecil, sesuatu yang terminal stamping mold sangat ahli dalam melakukannya dengan sangat akurat (dan mereka harus akurat untuk berfungsi dengan baik di dalam perangkat ini).

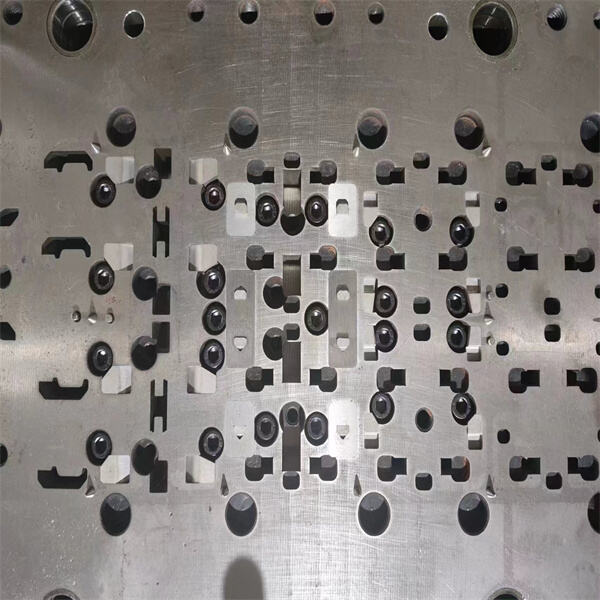

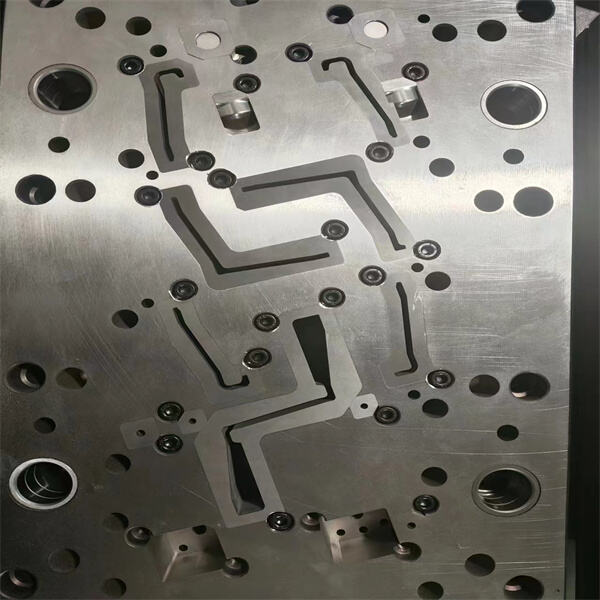

Sekarang, ketika berbicara tentang cetakan terminal, mereka adalah mesin khusus yang membantu dalam membuat bagian logam kecil yang memainkan peran penting bagi perangkat elektronik. Proses ini dimulai dengan lembaran logam besar. Palet ini dibawa ke gigi mesin dan dilalui melalui tahapannya. Mesin mulai dengan memotong logam menjadi segmen-segmen yang lebih kecil. Ini membentuk dan meninju logam untuk menciptakan sebuah terminal. Hal ini menghemat banyak waktu dan energi dibandingkan membuat setiap terminal secara manual satu per satu. Proses ini dilakukan oleh cetakan terminal dan menjaga setiap potongan agar memiliki ukuran dan bentuk yang sama. Kestabilan ini sangat penting untuk menghasilkan perangkat elektronik yang bekerja efisien.

Bahkan alat yang tampaknya sederhana seperti cetakan cap terminal memainkan peran penting dalam mengurangi biaya dan memungkinkan produsen untuk membuat jumlah yang lebih besar dari perangkat elektronik dengan cepat. Misalnya, ketika produsen butuh memproduksi sejumlah besar instrumen, cetakan cap terminal dapat digunakan untuk membuat beberapa jumlah terminal sekaligus. Ini tidak hanya mengurangi waktu yang diperlukan untuk memproduksi tetapi juga berarti lebih sedikit logam yang terbuang selama proses produksi. Menghemat uang produsen pada bahan, yang sangat penting bagi bisnis mereka, tetapi juga membantu kita semua dalam membuang lebih sedikit.

Cetakan penerus terminal memiliki banyak keuntungan dalam proses manufaktur. Mereka juga merupakan cetakan yang sangat cepat untuk digunakan, sehingga menghemat banyak waktu jika dibandingkan dengan membuat terminal secara manual. Ketika elektronik berada dalam permintaan tinggi, kecepatan ini menjadi sangat penting. Keuntungan kedua adalah bahwa aplikasi dari cetakan penerus terminal begitu berbeda sehingga setiap hasil akan memiliki ukuran dan bentuk yang identik. Hal ini membawa aspek esensial dalam dunia pembuatan perangkat elektronik berkualitas tinggi. Dan yang terakhir, penggunaan cetakan ini membantu meminimalkan limbah logam dalam produksi, yang menghasilkan penghematan biaya lainnya bagi produsen. Para pemimpin dapat membuat ratusan terminal menggunakan alat ini, dan mereka akan mampu memberikan perusahaan mereka dengan sejumlah besar perangkat elektronik yang diproduksi dengan cepat.

Cetakan Terminal Benar-benar telah merevolusi cara kami mengembangkan perangkat elektronik. Hal ini membuat seluruh proses lebih cepat, lebih efisien, dan hemat biaya. Cetakan terminal memungkinkan jumlah terminal yang akurat jauh lebih banyak untuk diproduksi dalam rentang waktu yang sama. Langkah ini telah memungkinkan kami memproduksi sejumlah besar perangkat elektronik dan membuat segalanya lebih mudah bagi semua orang karena ada bantuan kualitas tinggi untuk pemula. Kami semua menggunakan perangkat elektronik seperti smartphone, komputer, dan tablet dalam rutinitas harian kita yang memerlukan cetakan terminal untuk memproduksi barang-barang ini.

Hak cipta © Ningbo Wenzhou Technology Co., Ltd. All Rights Reserved - Kebijakan Privasi