Tel: +86-13777263762

Email: [email protected]

Tel: +86-13777263762

Email: [email protected]

Corrosion resistance: S136 steel can resist the corrosion effect of water vapor, weak organic acids, nitrates, carbonate, etc., especially suitable for molds that require exposure to these chemicals during the production process.

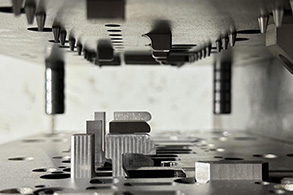

Abrasion resistance: S. steel 136 through quenching and tempering treatment, the surface hardness can reach HRC 50 to 52, with high wear resistance. Polishing performance. This steel has good polishing performance, can be processed into a specular state, and further enhances its corrosion resistance when used in a wet environment.

Dimensional stability: S136 steel shows excellent dimensional stability when quenching, ensuring the high precision of the mold and the dimensional consistency in long-term use.

Processing performance: This steel has good machability, including cutting, grinding and EDM, easy to meet the needs of complex mold manufacturing.

Economy: Due to its corrosion resistance and wear resistance, the mold made of S136 steel has low maintenance cost, long service life and economic benefits.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. All Rights Reserved - Privacy Policy